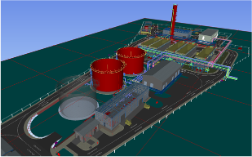

The client is a Turkey-based company engaged in the production and distribution of soda ash. To extract the soda, caverns are leached using fresh water, and the resulting brine is processed in a subsequent production facility. For the development of the cavern field northeast of Tarsus, comprising 22 caverns, PSE was commissioned to carry out the design and detailed engineering of the brine solution facilities.

The planning covered the entire building and station infrastructure for the brine solution facility, including all necessary auxiliary and secondary systems. This includes the main brine pumps, brine transfer pumps including a low-flow pump, nitrogen blanketing system, brine settling basin, brine transport pipelines, medium and low voltage switchgear, and the process control system.

PSE was commissioned to carry out the basic and detailed engineering.

THE TECHNICAL DATA OF THE PLANT

Brine Plant

- 5 Pump Units

- Total flow rate: 350 m³/h

- Operating pressure: 30 barg

- 5 × 420 kW connected load

Brine Transfer System

- 4 Pump Units

- Total flow rate: 1500 m³/h

- Operating pressure: 5 - 10 barg

- 2 × 160 kW / 2 × 180 kW connected load

Blanketing System:

- 2 Diesel Pumps

- 10 m³/h Dieseloil

- Operating pressure: 40 barg

- 22 kW Connected Load

- 100 m³ Feed Tank

Tank Farm

- 2 Tanks

- 5.000 m³/h per Tank