Storing natural gas in underground salt caverns is an essential part of security of supply. To minimise the probability of failure and increase redundancy, two withdrawal rods including the hot water supply have been planned and built. In the course of this, the withdrawal capacity of the existing plant was increased to 2x 60% and the existing line was dismantled. The renovation took place during ongoing operations.

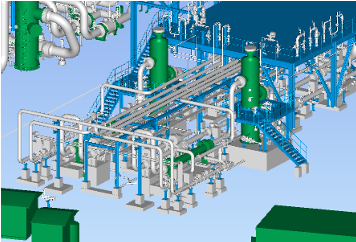

The withdrawal trains can be operated in parallel as well as in individual operation. In the withdrawal operation, the natural gas is fed via the separators to the shell-and-tube heat exchangers for the preheating. The pressure is then reduced to the pressure level of the gas drying by means of pressure reduction and flow control valves. The required amount of heat is provided in the primary heating circuit by a boiler system and transported to the heat exchangers via a hydraulic diverter by secondary circulation pumps.

As part of the project, PSE was assigned for the project management, planning as well as the construction and commissioning management.

The planning and construction of the withdrawal train included the entire station infrastructure for the withdrawal trains with the necessary auxiliary and ancillary systems. These include the separators, heat exchangers, pressure/volume control, preheating with secondary circulation pumps and hydraulic diverter.

THE TECHNICAL DATA OF THE PLANT

Withdrawal train 1 and 2:

- 25,000 to 1,100.000 Nm³/h Total withdrawal rate

- 110 to 199 barg Operating pressure

- 8.8 MW Total thermal duty